Beta-backscatter method

Determine a variety of layers with beta particles.

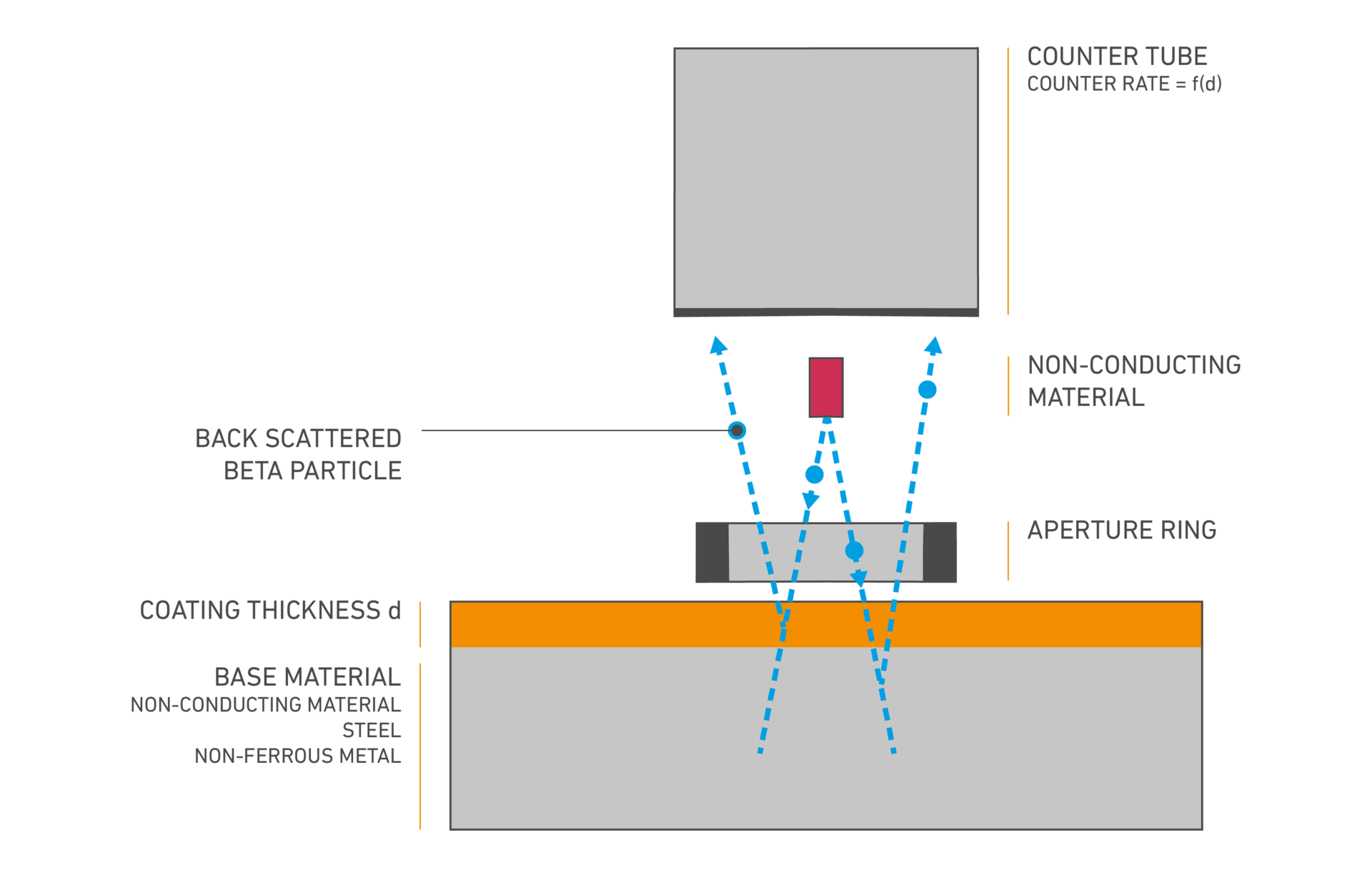

With the beta-backscatter method, you can measure the thickness of organic and anorganic layers on a wide variety of substrates using radiation from radioactive atoms. The measurement is non-destructive and, depending on the implementation, either non-contacting or contacting.

This is how the beta-backscatter method works.

In the beta-backscattering process, an isotope source emits beta particles (electrons). The beta particles are produced by the radioactive decay (more precisely: beta decay) of the atomic nuclei. The beta particles penetrate the coating and base material of the workpiece and are scattered by the atoms of both materials. To measure the coating thickness, the number of backscattered electrons is counted. If the layer thickness changes, the number of backscattered electrons also changes.

This makes it possible to measure the thickness of coatings of any material on any base material, provided that the atomic numbers (nuclear charge numbers) of the coating and base material differ sufficiently. With the beta-backscatter method, only the uppermost layer of a coating system can be measured. The method is a very universally applicable coating thickness measurement method.

Where is this process used?

- Very thick gold coatings on nickel, bronze or ceramics for decorative parts, art objects or in aerospace applications

- Silver in copper tubes for high-current contacts

- Thin oil and lubricant films on steel parts as light corrosion protection

- Thin layers of lacquer on electrical steel in the construction of transformers and electric motors

What factors can influence the measurement?

- Ernergy of the beta particles

- Density of the coating material

- Measuring time

- Difference between the atomic numbers of the coating and base material

- Composition of the coating

- Interlayers, composition of the base material

- Activity of the beta source

- Size of the aperture

The right calibration makes the difference

Fischer calibration standards are used to record a characteristic curve for the coating/base material combination to be measured with the appropriate beta source and taking into account the appropriate aperture (aperture opening diameter is decisive).

Energy of beta radiation

The thicker the layer, the greater the energy of the electrons from the radioactive atomic nuclei must be. At Fischer, the radionuclides C-14 (carbon-14), Pm-147 (promethium-147), Tl-204 (thallium-204) and Sr-90 (strontium-90) are available for a wide range of layer thicknesses.

Density

Differences between the densities of the layer of the calibration samples and the layer of the real samples can be compensated by using a simple correction factor (ratio of the densities).

Measuring time

Beta decay is a random process. This means that more or fewer atomic nuclei decay randomly every second, which results in fluctuations in the number of beta particles emitted during decay. This fluctuation increases the scatter of the measured coating thickness values. If this proportion of the measured value scatter is to be reduced, the measurement time must be increased - both during calibration and when measuring the real samples.

Difference between the atomic numbers of the coating and base material

The number of backscattered beta particles depends directly on the atomic atomic number of the coating and base material. If the difference in atomic numbers is small, the difference in the number of beta particles is correspondingly small. The smaller (larger) the difference in the number of beta particles, the larger (smaller) the measured value scatter. This can also be compensated for by a longer measuring time.

Composition of the layer

If the composition of the coating changes compared to the coating used for calibration, this can be compensated for by a correction factor in the case of small changes. In most cases, however, a new calibration with the changed coating is necessary.

Intermediate layers, composition of the base material

If the composition of the "metrological" base material changes due to intermediate layers or changes in the actual composition of the base material, this can in many cases be easily compensated for by calibrating the new, "metrological" base material into the existing characteristic curve (keyword: standardization).

Activity of the beta source

The activity of the beta source and therefore the number of beta particles it emits decreases over time. The influence of the decreasing activity on the measurement can be compensated for by a new normalization (calibration of the zero and end points of the characteristic curve) or by a new calibration. Lower activity usually requires longer measuring times.

Aperture opening size

Both the number of beta particles emitted from the beta source and the number of backscattered beta particles depend heavily on the size of the aperture. A separate calibration is therefore necessary for each aperture. The larger the aperture, the greater the number of beta particles and the shorter the measurement time can be.

Which standard is applied here?

Beta backscattering method according to DIN EN ISO 3543, ASTM B567 and BS 5411